The optimized layouts that have been generated are displayed on this page. The results consists of 3 sections...

| Available stock | The total number of stocks (of all materials) that were available for optimization. |

| Stocks Used | The total number of stocks that were used in the optimization. |

| Slits Required | The total number of slits that you had entered in the slits page. |

| Slits Cut | The total number of slits nested in all the layouts. |

| Utilization % | The overall utilization percentage. (Total length of slits + Offcuts)/(Total length of all the stocks used) |

| Drops/Offcuts | Numbers of rests, that are greater than the minimum offcut size. |

| Total Slit Width | The total width of the slits that is nested in meters or in feet (only if width units are inch or feet). |

| Total Stock Width | The total width of the stocks that will be required for the job in meters or in feet's. |

| Cost | The total cost, if the cost of the stocks have been specified. |

| Export a detailed output listing as an RTF file, and display it. | |

| Displays a short and concise output in RTF format. | |

| Updates the inventory. If stock from the inventory have been

consumed, it reduces their quantity in the inventory. It also updates

offcuts into the inventory, so that they are available for the next job.

See Update Inventory.

NOTE: To see the updated inventory, select the "Tools->Manage Inventory" menu. |

|

|

|

Print the labels for slits using barcodes. (Optional Add - On feature) |

| Print bar coded labels for offcuts generated in the job. (Optional Add - On feature) |

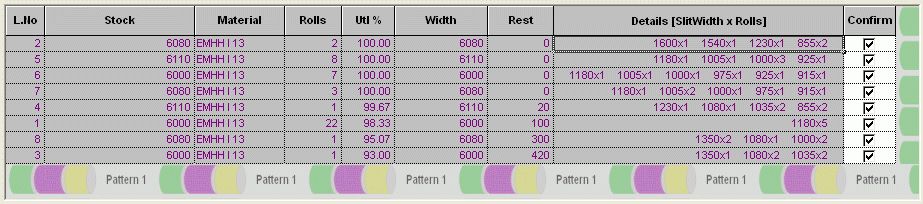

This table consists of the following columns.

| L.No | Layout Number |

| Stock | The stock name, on which the slits have to be cut. |

| Rolls | The number of times the layout has to be cut. |

| Utl % | The utilization percentage of the layout. |

| Width | The width of the stock. |

| Material | Material of the stock. |

| Rest | The value of the remaining piece. Note that the layouts 4 and 6 have offcuts, and are highlighted in Blue. |

| Details | The size x quantity of the pieces that have to be cut in the layout. For instance, layout One [1720x3 940x1], means piece of width 1720 has to be cut 3 times, and piece of width 940 has to be cut once. |

| Confirm | You can reject some layouts by un-checking this box. In such a case, some slits will not get made. You can re-optimize (renest) the remaining slits by clicking on the "Renest Remaining" button. This will not change the accepted layouts, but optimize the remaining slits, and add layouts to the result. |

![]()

When you select row in layout detail table, Its drawing will appear as above. This layout drawing shows you slits nested in it, its name, size and cut position. Also you can customize the layout drawing(Click Here). Whatever you do changes in layout drawing it same will appear in the RTF output.

| Layout | The details of the layout that is currently selected in the Layout Summary table is displayed here. In the above case the last layout (number 6) is highlighted. |

| Stock Used | The stock name and the stock size is displayed. |

| Slit | Name of the slit to be cut. |

| Position | The position of the knife/saw considering the cut width. |